Home » All Issues » Issue 2 » Planting with Precision

Planting with Precision

For Brad Qualischefski, farming runs in his blood. Spanning over four generations, his family have been farming since the 1930s and growing the business into the leading agribusiness it is today, Qualipac Agriculture.

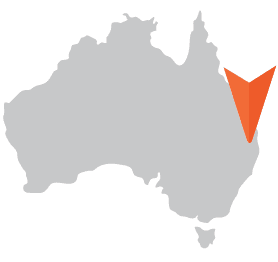

With farms across Queensland, Brad and his family operate their farming business on land in the Lockyer Valley, Inglewood and Allora. The farms mainly grow onions, broccoli, pumpkin, sweet corn, green beans and potatoes in addition to cattle and lucerne. Their family name has become synonymous with produce buyers at major supermarkets and central markets across

the country.

Qualipac Agriculture is very much a family run operation, with Brad looking after the farming side of the business, while his brother Troy handles the packing and marketing.

It’s fair to say that the last decade of unpredictable weather patterns, combined with the labour shortage challenge, have made farmers particularly vulnerable to the already challenging operating conditions of the industry over the past four years of drought and COVID related challenges.

The last two years of COVID have had its challenges, like many Australian businesses, ensuring they can keep up with the demand for their quality produce and operate with minimal disruption.

“Over a four year period from 2018 to 2022, we experienced a drought, followed by COVID 19, and then the floods came, so we were kept on our toes,” said Brad.

“It was a challenging four years as we farmed through both extremities of the weather and a pandemic no one could have predicted. It’s a credit to our staff and management who have been able to adapt to whatever the conditions were on any given day.”

“When there’s a flood, when it hits the paddock, you need to start again. In our case, we lost all our topsoil down the road during the last floods and raised the ground by half a metre. And with the cost of production due to increased seed and fertiliser costs, it means that we need to make every crop count.”

Brad has taken a key interest in introducing new technology into their farming operations –with optimised best practice of both sustainable and economic farming identified as a solution to overcome challenging times.

“The positives are the lessons we have learnt from these disasters. We can put these ideas in place to future proof our business in case it happens again.”

With the farms producing a wide variety of vegetables on a large scale, Brad needed efficient, dependable machinery, which is why he turned to Kubota.

“We use the Kubota Precision Planter for the pumpkin, green beans and sweet corn and we’ve got the Kubota Vegetable Planter for the onions. We’ve also got a Kubota compact disc with a seed hopper on top for cover and fodder crops,” Brad said.

Brad purchased his first Kubota in 2020, after seeing GEOSEED used on squash during a trip to New Zealand.

“They were growing organic squash and had been using mechanical weeding. As soon as I got back, I researched what was available in Australia and reached out to our local dealer, Terry from Black Truck & Ag from Gatton, who suggested the Kubota PP1450V Precision Planter,” Brad said.

Combined with the Kubota planters eDrive ISOBUS software, GEOSEED uses RTK GPS technology to precisely place each seed exactly where you want it across the whole field.

“THERE’S NO OTHER PLANTER IN AUSTRALIA THAT CAN DO WHAT THE KUBOTA DOES, AND WE ARE VERY HAPPY WITH THE RESULTS.”

“We plant our seeds in the shape of a diamond from north to west in the paddock. The PP1450V allows us to drive 45 degrees in any direction with a cultivator in the ground to pull out the weeds without pulling out the pumpkin plant itself.

“It means that we get better quality yield, better pumpkins, more efficient use of seed, which helps us survive as a business.

“We are very happy with the GEOSEED and are seeing really great results with inter row cultivating both ways. The next step for us is to automate weeding up the row. The more consistently you can place the seed, the easier it is for automation to become a reality. ”Pumpkins traditionally don’t have post emerge herbicides available and the pre emerge herbicides can upset the crop rotation with brassicas, making weed control one of the biggest challenges.

“Although it’s at the beginning of the growing process, the Kubota Precision Planter is an extremely important part of harvesting. You want to be able to get into the paddock and see the pumpkins, which you really can, ”Brad said.

“Traditionally we were doing a lot of hand weeding which took six people over a couple of days. We’re trying to reduce that basically to zero and all mechanical. ”By finding these efficiencies, Brad has been able to future proof the farm, ensuring that the family business remains firm for generations

to come.

While the farm moves to new practices for better efficiency, Kubota will remain a constant for Brad. “There’s no other planter in Australia that can do what the Kubota does, and we are very happy with the results. We’re after brands that don’t change dealers too often so we can build a relationship with our dealer, who knows what parts we need and the people to talk to, and we’ve found that in Kubota.”

For more information on Kubota Precision Planters and to find out where your nearest dealer is, visit: kubota.com.au